- Protection against corrosive media: Diaphragm seals isolate the gauge from corrosive liquids and gases, preventing damage to the indicator and ensuring accurate readings.

- High-temperature resistance: Diaphragm seals use materials that can withstand high temperatures, such as PTFE and Monel, allowing the application of the gauge in high-temperature applications without affecting accuracy.

- Vibration resistance: In high-vibration applications, diaphragm seals reduce the vibration transfer to the gauge, reducing the risk of damage and ensuring accuracy.

- Media compatibility: The diaphragm material can be selected based on compatibility with the process media, ensuring accurate readings and preventing damage to the gauge.

- Longer service life: A diaphragm seal with a pressure gauge in corrosive, high-temperature, and high-vibration applications can extend the service life of the pressure gauge, reducing the need for maintenance and replacements.

Providing problem solving and educational information for topics related to industrial steam, hot water systems, industrial valves, valve automation, HVAC, and process automation. Have a question? Give us a call at (800) 892-2769 | www.meadobrien.com

The Role of Industrial Diaphragm Seals

Benefits of Removable Reusable Insulation

- Acoustic Blankets & Shields

- Acoustic Blankets For Fan And Blower Housings

- Hydrophobic Insulation Blankets

- Safety Fire Blankets

- Safety Rain Shield Protective Enclosures

- Safety Spray Shield

- Safety Throw Blanket

- Thermal Blankets

- Improved energy efficiency: Blanket insulation helps to keep heat inside the facility during the winter and outside during the summer, which can significantly reduce the amount of energy needed to heat or cool the building.

- Lower costs: Reusable blanket insulation is a cost-effective solution for insulation because it can be used multiple times. This reduces the cost of insulation over the life of the building.

- Easy installation: Blanket insulation is simple to install and can be cut to fit any shape or size, making it easy to use in a variety of industrial settings.

- Durable: Reusable blanket insulation is made of heavy-duty materials that can withstand the wear and tear of an industrial environment.

- Safety: Insulation blanket can reduce the hazards of hot surfaces, electrical and fire hazards.

Jamesbury™ Quadra-Powr™ Spring Diaphragm Quarter Turn Actuators for Use in Both Modulating Control and On-Off Service

- Rolling diaphragm for minimum friction

- Low friction bearings – factory lubricated for lifetime

- Field reversible for spring to open or close simply by flipping actuator over

- Safety contained springs prevent hazards of inadvertent ejection during maintenance

- Corrosion resistant – two layer epoxy and polyurethane paint with stainless steel fasteners

- Adjustable stops for both open and closed positions

- Wide input pressure range – up to 7 bar (100 psi)

Industrial Actuators, Valves, and Positioners

Valves regulate fluid flow to provide accurate control and safety in any given process system, and methods of adjusting valve position are always required.

Commonly, valves are operated with handwheels or levers, although some must be regularly opened, closed, or throttled. In certain conditions, it is not always practical to position valves manually; hence actuators are employed instead of hand wheels or levers.

An actuator is a mechanism that moves or regulates a device, such as a valve. Actuators decrease the requirement for people to operate each valve manually. Valves using actuators can remotely control valve position, particularly crucial in applications where valves open and close or modulate fast and precisely.

Pneumatic, hydraulic, and electrical actuators are the three fundamental types.

- Pneumatic actuators employ air pressure to generate motion and are probably the most prevalent type of actuator utilized in process systems.

- Actuators powered by a pressurized fluid, such as hydraulic fluid, are called hydraulic actuators. Typically, hydraulic actuators of the same size produce more torque than pneumatic actuators.

- Electric actuators generate motion using electricity. Actuators usually belong to two broad categories: solenoid or motor-driven actuators.

Actuators position valves in response to controller signals and can be positioned rapidly and precisely to accommodate frequent flow variations. The instrumentation systems that monitor and respond to fluctuations in plant processes include controllers. Controllers receive input from other instrumentation system components, compare that input to a setpoint, and provide a corrective signal to bring the process variable (such as temperature, pressure, level, or flow).

You have a control valve when actuators pair with flow-limiting or flow-regulating valves. Generally speaking, control valves automatically restrict flow to provide accurate flow to a process to maintain product quality and safety.

Control valves can be linear, where the stem moves the valve disk up and down like globe valves, or rotational. Rotary control valves include butterfly valves, which open or close with a 90-degree rotation. The pneumatic diaphragm and electric actuators are the most prevalent on linear and rotational control valves.

Some valves require long stem travel or substantial force to change position. A piston actuator's higher torque is preferable to diaphragm actuators in these situations. Examples of piston actuators are rack and pinion and scotch-yoke designs.

Single-acting piston actuators control the air pressure on one side of a piston, and with higher air pressure, the piston moves within the cylinder and turns the valve. The air on the opposite side of the piston exits the cylinder via an air vent. With decreased air pressure, the spring expands, causing the piston to move in the opposite direction.

If air pressure falls below a predetermined threshold or is lost, the spring will push the piston to the desired position, referred to as the "fail" position (open or closed).

A double-acting piston actuator lacks a spring and has air supply ports on both ends of the cylinder. Increasing air pressure to the supply port moves the valve in one direction. Higher pressure air entering from the opposite supply port pushes the valve in the opposite direction. Filling the cylinder with air and releasing air from the cylinder is regulated by a device known as a positioner.

Typically, the control of pneumatic actuators occurs from air signals from a controller. Some actuators react directly from a controller, for instance, a pneumatic 3-15 PSI controller output. Sometimes, a controller signal alone cannot counteract a valve's friction or the process media's fluid pressure. This situation requires a separate, high pressure air supply and modulating it with a pneumatic or electro-pneumatic positioner. These devices regulate a high pressure air supply to ensure that an actuator has enough torque to position a valve accurately. The positioner responds to a change in the controller's air, voltage, or current signal and proportions the high pressure air to the actuator. Connecting the actuator stem to the positioner is a mechanical linkage. This mechanical connection is also known as a feedback connection. The link moves as the actuator stem moves up, down, or rotationally. The location of the connection informs the positioner when sufficient movement coincides with the controller's air signal. The controller's signal transmits to the positioner instead directly to the actuator, and the positioner regulates the air supply provided to the actuator.

Like other process components, actuators are prone to mechanical issues. Since actuator issues can negatively impact the operation of a process, it is essential to be able to recognize actuator issues when they occur. Frequently, an operator can notice an actuator fault by comparing the valve position indication to the position specified by the controller. For instance, if the position indicator shows the valve closed, but the flow indicator on the controller indicates that flow is still passing through the valve, the valve seat and disc are likely worn, enabling leakage through the valve.

Because there are so many different styles and designs of actuators, positioners, and valves and so many industrial applications, the combination possibility matrix is vast. You must discuss your application with a knowledgeable, experienced valve expert. The success of your project in terms of product quality, system cost, maintenance, and safety depends upon it.

Mead O'Brien

(800) 874-9655

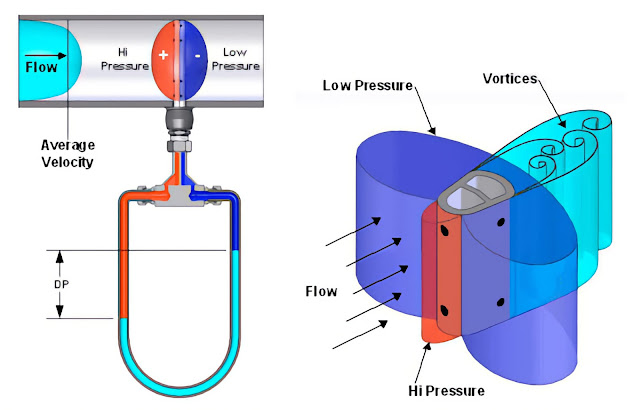

Setting the Foxboro/Schneider Electric IDP10-A Differential Pressure Transmitter for Measuring Flow

The Armstrong VERIS Verabar®

Verabar - Superior Signal Stability and Greater Resistance to Clogging

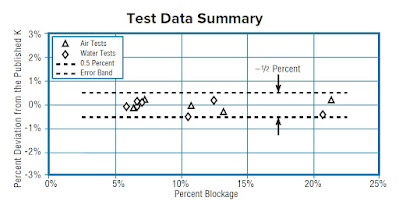

Verabar - Accuracy You Can Trust And the Data to Back It Up

Verabar - Lower Drag and Extended Turndown

Mead O'Brien Is Your Preferred Source for Institutional and Industrial Hot Water Systems and Equipment

With their manufacturer partners Armstrong International, Lattner Boiler Manufacturing, Shannon Global Energy Solutions, Clark Reliance, and Laars Heating Systems, Mead O'Brien supplies complete equipment packages - including pumps, storage tanks, piping, condensate & steam traps, valves, level instruments, computerized control systems, and high-efficiency insulation. Mead O'Brien's expertise covers heating systems of any capacity.

Mead O'Brien will also assist you in analyzing, designing, and installing boiler efficiency solutions with various fuel options that will reduce energy consumption and greenhouse gas emissions.

Mead O'Brien will professionally and expertly assist you with:

- Commercial projects where the mechanical design takes advantage of a boiler's high turndown and condensing design for optimum hot water efficiency.

- Commercial heating projects where hot water temperatures are to be above 160°F.

- Industrial process applications that require high-pressure hot water.

- Vertical Tubeless Boilers

- Horizontal Firetube Boilers

- Low-NOx Boilers

- Electric Boilers

- Steam Trap Surveys

- Thermal Assessments

- Hot Water System Surveys

Contact Mead O'Brien today to learn more. Call (800) 892-2769 or visit https://meadobrien.com.

Inflatable Seat Butterfly Valves - Posi-flate

The Posi-flate Inflatable Seat Butterfly Valve uses air pressure to inflate the seat against the disc and create a bubble-tight seal, resulting in minimal friction as the disc opens and closes. The Posi-flate inflatable seat automatically compensates for wear, providing longer valve life.

The resilient seated butterfly valve forces the disc into the static seat, causing impingement between the disc and seat, resulting in excessive damage, premature wear, and valve leakage.

The Posi-flate inflatable seated butterfly valve offers less friction, low torque, less wear, and longer valve life!

Unlike other valves that seal with friction, Posi-flate's unique butterfly valve uses an inflatable seat to seal with air pressure. Thus it requires less torque and a smaller actuator, resulting in lower overall valve cost. Plus, the seat automatically compensates for wear, providing longer valve life.

How Posi-flate Butterfly Valves Work

Closed, unsealed

As the valve rotates into the closed position, the disc makes only casual contact with the seat, reducing friction, wear, and torque requirements.

Closed, sealed

After the valve is closed, the seat inflates against the disc providing more sealing surface and an even pressure distribution against the disc.

Open, unsealed

Before the valve opens, the seat deflates. The disc is then free to rotate to the open position.

Posi-flate inflatable seated butterfly valve applications include:

- Material Control and Cut-Off Valve Applications

- Double Dump Valve Assembly Applications

- Dryer Valve Applications

- Outlet Valve Applications

- Pneumatic Conveying Valve Applications

- Vacuum Valve Applications

For more information about Posi-flate inflatable disc butterfly valves, contact Mead O'Brien at (800) 892-2769 or visit http://www.meadobrien.com.

A Commitment to Sustainability Starts With A Strong Value System and A Principled Approach to Doing Business

Mead O'Brien Mission

Carbon footprint reduction, increased throughput, and safety is our goal.

- Benchmarking Energy Consumption

- Analytical Measurements for Steam or Hot Water Generation

- Use of Instrumentation to Increase Throughput

- Use of Instrumentation to Increase Safety

- Control Environmental Leakage Rates Through Valves

- Optimize Valve Selection & Automation for Reliability

- Applications of Appropriate Safety Approvals Such as FM, API, NFPA, ANSI

- Valve Assembly and Testing Documentation

OmniSeal Expanding Plug Valves from Mead O'Brien

OmniSeal expanding plug valves are intended for applications requiring positive shut-off, verifiable zero leakage, double block and bleed (DB&B), and/or double isolation and bleed (DIB).

Mead O'Brien, Armstrong International, and Everactive: Partners in Decarbonization, Reducing Energy Waste and Sustainability

Mead O'Brien provides the experience and expertise, along with Armstrong's Sage™ IIoT platform and Everactive's battery-less technology, for a completely new energy monitoring and management approach for the process industries.

Consistent with the global move toward sustainability and energy efficiency, Mead O'Brien is proud to join Armstrong International and Everactive. This partnership allows us to work with our customers steam, hot water, and process heating applications in a completely new way. By combining our abilities and technologies jointly, we improve your production process and performance, reduce environmental emissions, increase safety, and help you reach your net-zero carbon goal.

Mead O'Brien, Armstrong International, and Everactive provide the technology and resources to assist you in developing a decarbonization road map customized to your facility and industry. Call us today for more information. 800-874-9655.

Mead O'Brien

https://meadobrien.com/netzerocarbon.

Kurt Armstrong and Bob Nunn Discuss Decarbonization, Steam Trap Monitoring, and Batteryless Technology

As the fight against climate change gets traction and the globe draws closer to decarbonization, net-zero has become our common goal. For more than a century, Armstrong has aided businesses in increasing efficiency, lowering energy consumption, and reducing emissions. Armstrong is the world's leader in thermal utility management.

Everactive, based in Silicon Valley, creates sensors that require so little power that they can continuously sense, process, and wirelessly transmit data by harvesting energy from their surroundings. Indoor solar (even in dimly lit facilities down to 100 Lux), thermal gradients, radio frequencies, vibration, and other energy sources are all possible.

Mead O'Brien transcribed the interview with Everactive CEO Bob Nunn and Armstrong CIO Kurt Armstrong where they discuss the global decarbonization movement and how monitoring steam traps might help reduce CO2 emissions. Read the transcript or watch the video here.

Mead O'Brien works closely with Armstrong on a regional basis to assist industry in achieving a net-zero objective efficiently and smoothly.

For more information, contact Mead O'Brien at (800) 892-2769 or visit https://meadobrien.com/netzerocarbon.

Steam Trap Replacement When Using the Armstrong TVS 6000UD

The Armstrong TVS 6000UD is a compact double isolation and bleed concept (up and downstream) with a 360° connector.

TVS 6000UD gives you double isolation inlet and outlet piston valves, bleed of inlet/outlet valves, a test valve, a strainer and a blowdown valve at trap inlet all merged together in a single compact 2-bolts universal connector.

With Armstrong’s 2-bolt universal connector block concept, the TVS 6000UD can be fitted with Armstrong’s inverted bucket, disc, thermostatic, thermostatic wafer, freely floating, and bimetallic steam traps. Any manufacturer’s 2-bolt steam trap can also be applied to Armstrong’s standard connector.

Benefits of the TVS 6000UD Trap Valve Station:

- Increased Safety when replacing steam traps thanks to double insolation and bleed concept

- Refurbishing existing trap stations without piping modification

- Trap Replacement in 5 minutes

- Simplified trap testing check trap operation easilly thanks to test valve at trap outlet

- Installation versatility. TVS 6000UD is adaptable to different steam trap technologies using 2-bolts

- Reduced costs a single compact trap station instead of 10 elements

- Reduction of potential leaks

- Connection flexibility (from ½’’ to 1’’ SW, BW, BSPT, NPT, flanges EN or ANSI)

- Piston valve technology

- 3-years guarantee

For more information about Armstrong products, contact Mead O'Brien. Call (800) 874-9655 or visit https://meadobrien.com.

White Paper :Ten Reasons to Consider Brushless DCV Motors in Electric Valve Actuators

This paper, courtesy of Flowserve Limitorque, aims to investigate the most recent advancements in these motors, consider alternatives, and discuss how to make an informed decision about when and where to use BLDC motor technologies.

Brushless DC motors are synchronous motors powered by a direct current source via an electric controller rather than the brush/commutator mechanism used in brushed DC motors. The electric controller, an integrated inverter/switching power supply, generates an alternating current signal that drives the rotor. Electronically commutated motors, ECMs, or EC motors are other names for them.

Brushless DC electric (BLDC) motors have been around for nearly 50 years, but their use for intelligent actuation is relatively new. Their adaptation is critical to the improvement of process control and plant safety systems.

Wireless Steam Trap Monitoring and Networking from Armstrong International and Mead O'Brien

Armstrong International's Everactive is a breakthrough wireless steam trap monitoring technology that works seamlessly with Sage®, Armstrong's accurate, reliable, leading-edge technology and software package for monitoring, measuring, auditing and includes complete documentation.

Everactive is wireless and batteryless technology. It is affordable, maintenance-free, simple to install, and works with all brands and models of steam traps. You'll receive warnings when traps fail, allowing you to fix or replace failing traps before they cause major steam system problems. The ground-breaking technology maximizes efficiency and dependability while reducing the size of the IT infrastructure footprint.

Everactive sensors send trap data to SAGE®, where you can evaluate real-time trap activity, view and resolve failure alerts, and better manage your whole steam trap population.

Whether you want to maintain a constant eye on important process traps or want to monitor your whole steam trap population, the decision is yours, and you can do it without the hassle and expense of battery maintenance.

For more information about Armstrong products, contact Mead O'Brien. Call (800) 874-9655 or visit https://meadobrien.com.