The Armstrong Veris Verabar averaging pitot flow sensor provides unsurpassed accuracy and reliability. With its solid one-piece construction and bullet shape, the Verabar makes flow measurement clog-free and precise. Its unique sensor shape reduces drag and flow-induced vibration, and the location of the low-pressure ports eliminates the potential for clogging and improves signal stability.

Verabar - Superior Signal Stability and Greater Resistance to Clogging

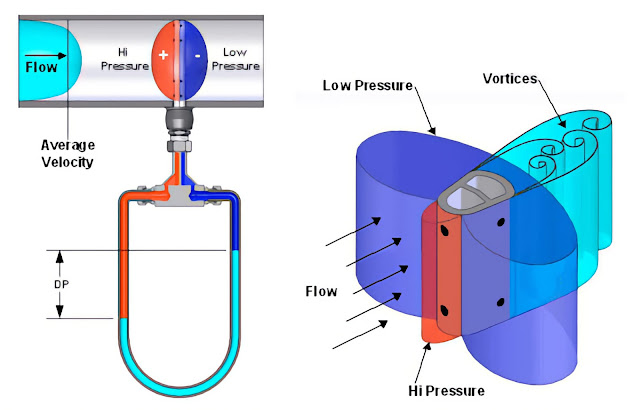

Clogging can occur in low-pressure ports in or near the partial vacuum at the rear of the sensor. The Verabar design finds the low-pressure ports on the sides of the sensor, forward of the fluid separation point, and turbulent wake area, virtually eliminating clogging and producing an extremely stable signal.

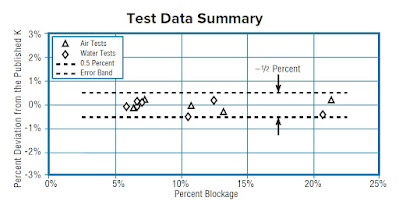

Verabar - Accuracy You Can Trust And the Data to Back It Up

The unique and exclusive breakthrough in improved accuracy derived from developing a verified theoretical model predicts the Verabar flow coefficients. The verified theoretical model eliminates the need for calibration tests to characterize the flow coefficients. Without such a model, the uncertainty of the flow coefficients dramatically increases, and expensive calibration is required. Empirical test data from independent laboratories verified the theoretical model and flow coefficients as a constant, independent of the Reynolds number and within ±0.5% of the predicted value. The Verabar Flow Test Report (ED-100) includes the theoretical model and test data derivation.

Verabar - Lower Drag and Extended Turndown

Golf balls fly farther because they have a dimpled surface that lowers aerodynamic drag. The grooves and roughness on the Verabar’s frontal surface apply the same principle. This simple design feature relieves the partial vacuum at the rear of the sensor, reducing the pressure drag and extending the accuracy and rangeability to very low velocities.