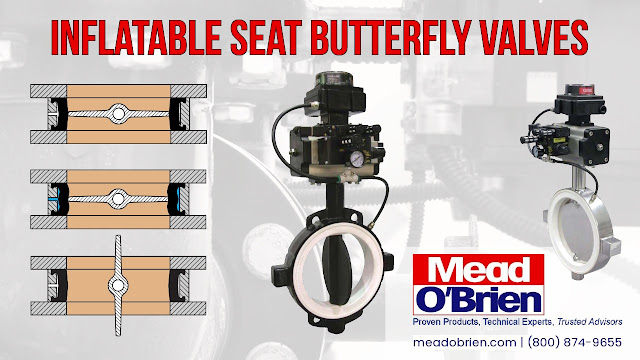

In the case of inflatable seat butterfly valves, the design includes an inflatable seat. This seat is typically a resilient (often elastomeric) liner that can be inflated or deflated to achieve tight shutoff or to allow the disc to rotate freely.

Unique Operation:

- Sealing Mechanism: The seat is inflated when the valve needs to be closed tightly to prevent any leakage. The inflation pushes the seat tightly against the disc, creating a tight seal, which ensures zero leakage. This mechanism makes the inflatable seat butterfly valve distinct from traditional butterfly valves.

- Free Rotation: When the valve needs to be operated (either to be opened or to throttle flow), the seat is deflated. This deflation allows the disc to rotate freely without rubbing against the seat.

Advantages:

- Enhanced Sealing: The primary advantage is achieving a very tight shutoff. The inflatable seat can seal tightly against the disc, preventing potential leakage, even when particles might be trapped between the disc and the seat.

- Extended Life Span: Because the disc does not rub against the seat during operation, the wear and tear on the disc and the seat are minimized, prolonging the valve's life.

- Versatility: Suitable for handling both liquids and dry bulk materials, especially useful in industries where particle entrapment is a concern.

- Reduced Maintenance: Maintenance intervals can be extended due to the reduced wear and tear on the valve components.

- Optimal for Slurry Applications: Their design ensures minimal clogging or obstruction, making them suitable for slurry applications.

Industrial Applications:

Inflatable seat butterfly valves are especially beneficial in industries where tight sealing and prevention of contamination are critical.

- Pharmaceuticals: Where contamination can compromise the integrity of products.

- Food & Beverage: Ensuring a sanitary environment and preventing contamination.

- Chemical Processing: Handling aggressive chemicals that might leak in regular valves.

- Mining: Dealing with slurry and other particle-laden fluids.

- Pulp & Paper: Handling pulps, sludges, and other semi-solid materials.

Posi-flate, headquartered in St. Paul, Minnesota, is the worldwide leader in inflatable seat butterfly valves. Comparative tests show that the Posi-flate butterfly valve excels over competitors, with a one to three million cycles lifespan, especially in abrasive conditions. The Posi-flate Series 585/586 is tailored for extreme conditions, catering to heavy-duty needs and high pressures. These valves fit sizes from 2" (50mm) to 24" (600mm), compatible with both ANSI and metric flanges. A comprehensive range of actuators, switches, and controls are available for various applications.

In summary, inflatable seat butterfly valves offer a unique and effective solution to many industrial challenges. Their ability to provide a tight seal, even under challenging conditions, makes them invaluable in various applications where leakage or contamination could be costly.

https://meadobrien.com

(800) 874-9655