The gas-powered scotch yoke actuator is a mechanical device designed to convert linear motion into rotary motion, primarily used for valve actuation in the oil and gas industry and other industrial applications requiring precision control of fluid flow. This actuator is particularly advantageous for heavy-duty and high-torque applications, offering reliable and efficient operation with minimal maintenance. Here's a detailed overview of how it operates and its primary application:

Operation:

- Gas supply: The gas-powered scotch yoke actuator uses pressurized gas as the driving force, which, depending on the specific application and site requirements, the gas source is a natural gas pipeline, an onsite compressor, or bottled gas.

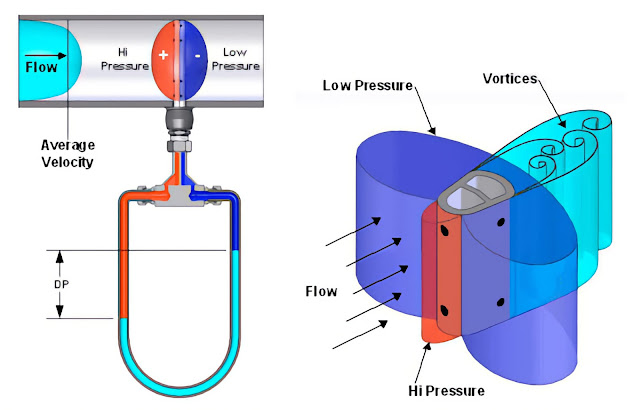

- Pneumatic cylinder: The gas enters the pneumatic cylinder, which is the core component of the actuator. The cylinder contains a piston that moves linearly when pressurized gas is applied.

- Scotch yoke mechanism: The linear motion of the piston is converted into rotary motion using the scotch yoke mechanism. The scotch yoke consists of a yoke (a slotted, U-shaped component) attached to the piston rod and a pin mounted on the rotating output shaft. The yoke slides along the pin as the piston moves linearly, causing the output shaft to rotate.

- Output shaft: The output shaft's rotation is transferred to the valve stem, causing the valve to open or close, depending on the direction of the rotation. The shaft is connected to the valve using a coupling, which ensures proper alignment and torque transmission.

- Spring return mechanism: Some gas-powered scotch yoke actuators have a spring return mechanism, which enables the valve to return to a predetermined fail-safe position in the event of a loss of gas supply or system failure.

Primary application: The primary application of the gas-powered Scotch yoke actuator is in the oil and gas industry, where it controls various types of valves, such as ball valves, butterfly valves, and plug valves. These valves are essential for regulating the flow of oil, gas, or other fluids in pipelines, processing plants, and other facilities.

The actuator's high torque capabilities make it suitable for heavy-duty applications, such as large-diameter or high-pressure valves. Additionally, the gas-powered design offers several advantages over electric or hydraulic actuators, including lower operating costs, reduced environmental impact, and compatibility with remote or hazardous locations where electricity or hydraulic power may not be readily available.

Limitorque has established a dominant position in the gas-powered scotch yoke actuator market, owing to its reputation for delivering high-quality, reliable, and efficient products. Their actuators are known for their durability and low maintenance requirements, making them a preferred choice for heavy-duty applications in the oil and gas industry. The company's commitment to continuous innovation and its extensive experience in the field has allowed them to develop customized solutions to address the unique challenges faced by its customers. Furthermore, Limitorque's strong global presence and extensive support network ensure they provide exceptional after-sales service, reinforcing their position as a trusted leader in the market.

Mead O'Brien

(800) 892-2769