Steve Huffman, VP of Sales and Marketing for Mead O'Brien, and Greg McMillan, retired Senior Fellow from Solutia/Monsanto and monthly "Control Talk" columnist for Control magazine, discuss how automation is far more important than recognized and that we each play a role in helping everyone appreciate the incredible significance of opportunities created.

Providing problem solving and educational information for topics related to industrial steam, hot water systems, industrial valves, valve automation, HVAC, and process automation. Have a question? Give us a call at (800) 892-2769 | www.meadobrien.com

Showing posts with label automation. Show all posts

Showing posts with label automation. Show all posts

The "Automation Multiplier Effect" and the Much Overlooked Importance of Automation

Steve Huffman, VP of Sales and Marketing for Mead O'Brien, and Greg McMillan, retired Senior Fellow from Solutia/Monsanto and monthly "Control Talk" columnist for Control magazine, discuss how automation is far more important than recognized and that we each play a role in helping everyone appreciate the incredible significance of opportunities created.

Understanding Industrial Valve Actuators

|

| Automated Pneumatic Ball Valve (Jamesbury) |

Thanks to actuators, multiple valves can be controlled in a process system in a coordinated fashion; imagine if, in a large industrial environment, engineers had to physically adjust every valve via a hand wheel or lever! While that manual arrangement may create jobs, it is, unfortunately, completely impractical from a logistical and economic perspective. Actuators enable automation to be applied to valve operation.

|

| Pneumatic actuator (Jamesbury Quadra-Powr) |

Pneumatic actuators utilize air pressure as the motive force which changes the position of a valve. Pressurized-liquid reliant devices are known as hydraulic actuators. Electric actuators, either motor driven or solenoid operated, rely on electric power to drive the valve trim into position. With controllers constantly monitoring a process, evaluating inputs, changes in valve position can be remotely controlled to provide the needed response to maintain the desired process condition.

Manual operation and regulation of valves is becoming less prevalent as automation continues to gain traction throughout every industry. Valve actuators serve as the interface between the control intelligence and the physical movement of the valve. The timeliness and automation advantages of the valve actuators also serve as an immense help in risk mitigation, where, as long as the system is functioning correctly, critical calamities in either environmental conditions or to a facility can be pre-empted and quickly prevented. Generally speaking, manual actuators rely on hand operation of levers, gears, or wheels, but valves which are frequently changed (or which exist in remote areas) benefit from an automatic actuator with an external power source for a myriad of practical reasons, most pressingly being located in an area mostly impractical for manual operation or complicated by hazardous conditions.

|

| Electric Actuator (Limitorque) |

Thanks to their versatility and stratified uses, actuators serve as industrial keystones to, arguably, one of the most important control elements of industries around the world. Just as industries are the backbones of societies, valves are key building blocks to industrial processes, with actuators as an invaluable device ensuring both safe and precise operation.

Mead O'Brien VP Elevated to ISA Fellow

|

| ISA Fellows 2016 |

|

| Steve Huffman |

Steve Huffman, VP of Sales and Marketing at Mead O'Brien will be one of the honorees at the 54th Annual ISA Honors & Awards Gala to be held on 24 September 2016 in Newport Beach, California.

Steve is being recognized for leading the effort to create the US Department of Labor’s Automation Competency Model for automation professionals.

Congratulations to Steve for this achievement and for his many years of service to the instrumentation and automation community.

Your Career in Process Automation May Just Save The World

Did the title get your attention?

Here's a thesis for you to consider: People entering the workforce who are interested in meaningful careers should strongly consider industrial control and automation.

Wouldn't you like a career where you could:

- Help solve world energy

- Help provide clean water

- Help solve world hunger

- Help clean and sustain the environment

- Help meet chemical & mineral needs

- Help provide material goods

The following presentation by Steve Huffman, Vice President of Mead O'Brien and Chairman of Government Relations for the Automation Federation, provides an interesting argument about the importance of people in the changing world of process automation. Enjoy.

The Rack and Pinion Style Pneumatic Valve Actuator

|

| Rack & Pinion Actuator (courtesy of Flowserve Automax) |

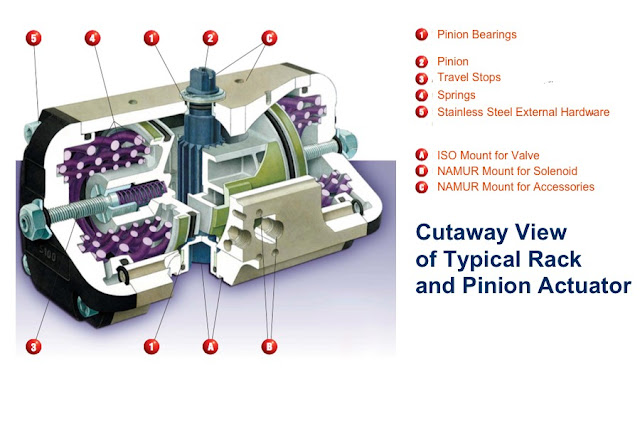

Pneumatic actuators can be further categorized as scotch yoke design, vane design, and the subject of this post - rack and pinion actuators.

Rack and pinion actuators provide a rotational movement designed to open and close quarter-turn valves such as ball, butterfly, or plug valves and also for operating industrial or commercial dampers.

The rotational movement of a rack and pinion actuator is accomplished via linear motion and two gears. A circular gear, referred to a “pinion” engages the teeth of a linear gear “bar” referred to as the “rack”.

Pneumatic actuators use pistons that are attached to the rack. As air or spring power is applied the to pistons, the rack is “pushed” inward or “pulled” outward. This linear movement is transferred to the rotary pinion gear (in both directions) providing bi-directional rotation.

|

| Visual of rack and pinion (courtesy of Wikipedia) |

Most actuators are designed for 100-degree travel with clockwise and counterclockwise travel adjustment for open and closed positions. World standard ISO mounting pad are commonly available to provide ease and flexibility in direct valve installation.

NAMUR mounting dimensions on actuator pneumatic port connections and on actuator accessory holes and drive shaft are also common design features to make adding pilot valves and accessories more convenient.

|

| Fully automated valve with rack and pinion actuator, solenoid, and limit switch. |

For more information on any pneumatic or electric valve automation project, contact:

Mead O’Brien, Inc.

www.meadobrien.com

10800 Midwest Industrial Blvd

St. Louis, Missouri 63132

Phone (314) 423-5161

Toll Free (800) 874-9655

Fax (314) 423-5707

Email: meadstl@meadobrien.com

Labels:

actuation,

actuator,

automation,

Automax,

Flowserve,

Illinois,

Indiana,

Kansas,

Kentucky,

Missouri,

pneumatic,

rack and pinion,

valve actuator

Automation Competency Model Helps Guide Future Technical Workforce

Author, Stephen R. Huffman, Vice President, Marketing and Business Development, at Mead O’Brien, Inc.

Published: InTech Magazine, July-Aug 2015

Eight years ago, the Automation Federation (AF) delegation told an audience at the Employment and Training Administration (ETA) about the people practicing automation careers in industry. Not long before our visit, the ETA, part of the U.S. Department of Labor (DOL), had worked with the National Institute of Standards and Technology (NIST) to develop a “competency model” framework based on the needs of advanced manufacturing. The ETA was eager to engage AF and ISA to use our tiered framework to develop a competency model for the automation profession.

Eight years ago, the Automation Federation (AF) delegation told an audience at the Employment and Training Administration (ETA) about the people practicing automation careers in industry. Not long before our visit, the ETA, part of the U.S. Department of Labor (DOL), had worked with the National Institute of Standards and Technology (NIST) to develop a “competency model” framework based on the needs of advanced manufacturing. The ETA was eager to engage AF and ISA to use our tiered framework to develop a competency model for the automation profession.After developing the preliminary model, hosting subject-matter expert (SME) meetings facilitated by the DOL to finalize our work, and then testing the model with several automation managers against their own criteria for validity, we rolled out the Automation Competency Model (ACM) to educators, government, and industry in 2008. Since then, it has been a tool for educators and parents to show students what automation professionals do, management to understand the skill sets their employees need to be effective and to use as a tool for gap analysis in reviews, program developers to create or alter curricula for effective education and training, and lawmakers to understand how U.S. manufacturing can be globally competitive and the jobs needed to reach that goal.

In the lower tiers, the model identifies necessary soft skills, including personal effectiveness, academic, and general workplace competencies. Automation-specific work functions, related competencies, and references (e.g., standards, certifications, and publications) are detailed in tier 5. In short, the model stakes out our professional territory and serves as a benchmark for skill standards for all aspects of process and factory automation. Previously, parts of the academic community and some U.S. lawmakers and agencies had the misconception that industrial automation and information technology (IT) are synonymous. Although there has been some convergence between IT and operational technology (OT), much of that perception has changed. OT-based industrial automation and control systems (IACS) were a focus in the recent cybersecurity framework development organized by NIST in response to the presidential executive order on cybersecurity for critical infrastructure.

The ACM has been a great tool for the AF to use to draw new organizational members and working groups, who visualize the big picture in automation career development. Also, we are telling our story and forming partnerships with science, technology, engineering, and math (STEM) organizations such as FIRST and Project Lead the Way. Since forming in 2006, AF now has 16 members representing more than 500,000 automation-related practitioners globally. After two three-year critical reviews, the ACM is still the most downloaded competency model on the DOL website. As a result of our work in creating the ACM and the IACS focus in cybersecurity framework meetings, the DOL asked AF to review a heavily IT focused Cybersecurity Competency Model. After adding IACS content and the philosophy of plant operation (versus IT) cybersecurity, the model released was a much stronger tool with wider applicability.

Recently, ISA, as a member of the American Association of Engineering Societies (AAES), presented the development of the ACM to AAES leadership as a way to provide tools for lifelong learning in the engineering profession. AF/ISA was once again invited to work with the DOL and other AAES member societies to lead in developing an Engineering Competency Model. The model framework and our experience in ACM development enabled us to identify the front-end skills, necessary abilities, knowledge to be developed, and academic prerequisites for any of the disciplines, plus industry-wide competencies from the perspective of all engineering-related plant functions: design, manufacturing, construction, operations and maintenance, sustainability and environmental impact, engineering economics, quality control and assurance, and environmental health and safety—with emphasis on cyber- and physical security, and plant safety and safety systems.

Now the societies dedicated to each vertical discipline listed in tier 5 will begin to identify all critical work functions, detail all competencies within each function, and note the reference materials. It is important for the participants to see the big picture, consider the future, and keep an open mind; agreement typically comes easily when SMEs participate with that mindset. Once the model through tier 5 is complete, job titles and job descriptions are created. When the DOL accepts the model, the U.S. government officially recognizes these positions. We hope the emerging Engineering Competency Model will be a great tool to address the overall skilled worker shortage. If the automation model is any indication, the new engineering model will have a large impact on achieving the skilled workforce goal.

Innovative Pressure Transmitter Automatically Selects Calibration Range

|

| Foxboro S Series |

Foxboro, through its patented “Foxcal” firmware allows the Foxboro models IDP10S, IGP10S, IAP10S transmitters to automatically select and use any of 11 preset calibration ranges (stored in firmware). These calibration ranges cover the full pressure range of the transmitter. Upon installation, the S Series transmitter automatically selects the appropriate calibration range based on application inputs; and, if application inputs change, automatically transitions to another, more appropriate calibration range – all while maintaining a reference accuracy of 0.05%.

It is the first pressure transmitter to incorporate not only multiple calibration curves, but the ability to automatically select and transfer between them in real time. With the new technology, users have a wide-range capability with high reference accuracy for all industries requiring precise differential, gauge, and absolute pressure measurement. Additional benefits are inventory reduction and simplified tech training. Because of their wide turndown range with such high reference accuracy, adopting one model of S Series transmitter eliminates the need to inventory, learn, and maintain multiple transmitter models that handle more limited ranges (e.g., 150 psi, 800 psi, 4000 psi).

The Foxboro IDP10S datasheet can be downloaded here.

Or, you can review it online below:

For more information, contact:

Mead O’Brien

(800) 892-2769

sales@meadobrien.com

www.meadobrien.com

Cybersecurity, ISA, and Automation Federation and How We Got Here

Author, Stephen R. Huffman, Vice President, Marketing and Business Development, at Mead O’Brien, Inc.

Published: InTech Magazine, May-June 2015

|

| Cybersecurity and Automation |

Technical leaders had the foresight to create the ISA99 standards committee back in 2002. They recognized the need for cybersecurity standards in areas outside of the traditional information technology (IT), national security, and critical infrastructure areas of concentration at the time. In the following years, a number of ISA99 committee members spent time and effort advocating and even testifying on Capitol Hill about our profession, which was not well defined, and our cybersecurity efforts therein, which were not well discerned from IT perceptions.

When Automation Federation (AF) refocused its efforts in 2007 with both automation profession advocacy and industrial automation and control system (IACS) cybersecurity as two of its strategic imperatives, we ventured forth to Capitol Hill with a message and a plan. We found that in general our lawmakers equated process and industrial automation as “IT” and thought that IT was already addressing cybersecurity in terms of identity theft and forensics, and that the Department of Defense was handling cyberprotection for national security. For the next several years, AF built its story around cyberthreats in the operational technology (OT) area and how ISA99 through its series of standards, technical reports, and work group output was providing guidance for asset owners, system integrators, and control system equipment manufacturers specifically for securing IACS.

The operating philosophy of IT cybersecurity versus OT cybersecurity is quite different. Although the approach of shutting down operations, isolating cybersecurity issues, and adding patches may work well to mitigate IT breaches, the same cannot be said for operating units in a real-time process. In short, it really is not feasible to “reboot the plant.” The message resonated enough for us to help create the Liebermann-Collins Cybersecurity Senate Bill introduced in 2012, but opposition (more political than reasonable) doomed this first effort.

In 2013, the President issued Executive Order 13636 for enhancing cybersecurity protection for critical infrastructure. It included directing the National Institute of Science and Technology (NIST) to establish a framework that organizations, regulators, and customers can use to create, guide, assess, or improve comprehensive cybersecurity programs. Of the more than 200 proposals submitted by organizations receiving a request for proposal, almost all were IT-based. The AF/ISA submittal took the perspective of operational technology backed by the strength of the existing ISA99 set of standards. After a set of five framework meetings of invited participants, including the AF “framework team,” over the course of 2013, the OT and IACS teams were much more successful in defining the needs, and the automation message was much better understood. NIST personnel with legislative experience with AF on the 2012 Senate bill understood that private industry is a key piece of the cybersecurity and physical security puzzle.

AF organized a series of NIST framework rollout meetings in 2014 around the country with attendees from the AF team, NIST, and the White House. The meetings were hosted by state manufacturing extension partnerships, which are state units of NIST. After these meetings and more work with Senate lawmakers, a bipartisan Senate bill, The Cybersecurity Enhancement Act, was signed by the President and put into law in December 2014 (www.congress.gov/bill/113th-congress/senate-bill/1353). In summary, the act authorizes the Secretary of Commerce through the director of NIST to facilitate and support the development of a voluntary, consensus-based, industry-led set of standards and procedures to cost effectively reduce cyberrisks to critical infrastructure. As you can imagine, ISA99, now IEC/ISA 62443, will play a more prominent role in securing the control systems of industry in the future through a public-private information-sharing partnership. Thanks for the foresight and fortitude of the ISA99 standards committee.

Subscribe to:

Posts (Atom)