Cost cutting is a fact of life for all industries. Whether it be for more efficient operations, or complying to current regulations, the need to build a better mouse trap is always present.

A very promising cost-cutting technology is wireless instrumentation. Wireless provides a compelling argument to change when you consider installation and overall cost effectiveness. Even more so when the application is located in a harsh environment, or where toxic or combustible situations exist. These robust devices provide critical performance data around the clock in the most inhospitable place in the plant, and operate through rain, wind, high temperatures and high humidity.

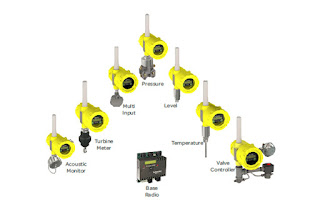

Untethered by cables and hard-wiring, wireless instrumentation is easier to deploy and monitor. Wireless transmitters are available for monitoring virtual all process variables such as pressure, temperature, level, flow, density, and acoustics. Networks of up to 100 (900 MHz) field devices can be created and then monitored by a single base radio or access point, with a typical communication range of over 1/2 mile. By communicating through the industry standard, Modbus, compatibility between device manufacturers is ensured.

The most obvious reason for choosing wireless over hard-wiring is the cost savings associated with running wires and cables. Savings estimates as high as 70% can be realized by deploying wireless field devices, compared to the same application using cables. Additional savings are realized when you consider that these devices use batteries and that the cost of adding to a network is borne only by the cost of the new device.

Wireless instruments also provide significant benefits in safety and compliance by keeping personnel out of hazardous areas. Areas that would require occasional human visitation can be safely monitored through remote monitoring.

So, what's the hold up? If the benefits are so clear, and the argument is so strong, why is there still reluctance to embrace wireless technology?

There are three main concerns:

Reliability

Wireless instrumentation must provide the same reliability (real and perceived) as traditional wired units. Every engineer, operator and maintenance person knows wires. Troubleshooting wires is easy, and understanding the failures of wires is basic - the wire is either cut or shorted. With wireless however, air is the communication medium and radio signals replace wires. Radio signals are more complicated than wires in terms of potential problems. For instance, signal strength, signal reflection and interference are all possible impediments to reliable links.

The good news is that radio frequency design is continuously improving, and the use of new and advanced technologies, such as frequency hopping receivers and high gain antennas, are enabling wireless devices to create highly reliable links.

Adapting to Existing Infrastructure

Wireless instrumentation networks have to adapt to the existing environment and the placement of structures and equipment. Most times it's just not practical to relocate equipment just to create a reliable wireless link. This can make it challenging to find the optimum location for a base radio or access point that is capable of providing a reliable communication link to your wireless instruments. Furthermore, accommodating the best strategy for one wireless device could negatively affect links with other devices on the same network.

The challenges of adaptability are being overcome by providing better frequency bands (such as 900 MHz). These bands provide longer range, the ability to pass through walls, and offer more saturating coverage. Other ways to overcome adaptability concerns are through the use of external, high gain antennas mounted as physically high as possible, and also by using base radios with improved receiving sensitivity.

Integration with Existing Communications

Engineers, operators, and maintenance crews are challenged by integrating wireless instrumentation networks with other, existing, field communications systems. The issues of having to manage and troubleshoot multiple networks adds levels of complexity to existing systems. This creates a conflict between the financial argument to adopt wireless instrumentation and the possible costs to increase the data gathering capabilities of an existing system. For instance, SCADA systems need to be able to handle the additional data input from wireless devices, but may not have the capacity. Adding the additional data capacity to the SCADA system can be expensive, and therefore offset the wiring and cabling savings.

The financial argument for industry to adopt wireless instrumentation networks is persuasive, but its acceptance in the process control industry is slow. Reliability, acclimation, and integration are all challenges that must be overcome before widespread adoption occurs. Eventually though, the reality of dramatically reduced deployment and maintenance costs, increased safety, and improved environmental compliance will tip the scale and drive wireless as the standard deployment method.

Always consult with

an experienced applications engineer before specifying or installing wireless instrumentation. Their experience and knowledge will save you time, cost, and provide another level of safety and security.