Providing problem solving and educational information for topics related to industrial steam, hot water systems, industrial valves, valve automation, HVAC, and process automation. Have a question? Give us a call at (800) 892-2769 | www.meadobrien.com

Showing posts with label Kansas. Show all posts

Showing posts with label Kansas. Show all posts

Top Ten List for Improving Process Steam Systems

10. Ensure the steam boiler is sized large enough to meet the current system consumption and possibly future expansion. Remember: BTUs needed to get feedwater to saturation temperature, and heat loss in piping due to insulation inefficiency.

9. Size steam distribution piping for 6000 FPM velocity below 50 PSIG steam pressure and 8000 FPM velocity for 50 PSIG and above. Remember: lower steam pressure has higher specific volume than higher pressure.

8. Make sure drip legs with drip steam traps are used to remove condensate from steam distribution lines to prevent thermal shock water hammer and poor quality steam delivered to the heat exchanger. Remember: drip legs should be about 2 ft. long and the same size as the steam pipe up to 4” and ½ the size of the pipe above 4”

7. Use equal percentage inherent trim characteristic control valves for process temperature control on steam sized to operate between 20 and 80% open, min to max. Remember: non-linearity in the form of high gain under partial steam load conditions are plotted as the inverse of the =% curve to become close to linear in the installed trim characteristic applied to the process.

6. Use supplemental thermostatic air vents and vacuum breakers (or a single device that does both) on large cavity heat exchangers. Remember: air is an insulator and is detrimental to surface temperature, and vacuum, formed by steam condensing and not replaced with an equivalent volume of steam, prevents the gravity flow of condensate from the exchanger to a steam trap allowing for the potential of thermal shock water hammer and/or internal corrosion.

5. Select the proper steam trap for the application. On modulated steam applications, the F&T (float & thermostatic) steam trap and inverted bucket steam trap are both acceptable depending on performance characteristics desired. Remember: steam traps must 1) stop the flow of steam to allow desired steam pressure to be maintained on the heat exchanger while latent heat is transferred to the process, 2) remove condensate in the heat exchanger simultaneously, and 3) remove non-condensable gases.

4. Ensure the steam trap can provide the capacity at low differential and can overcome static head pressure created by an overhead condensate return. Remember: if that condition can occur, use a mechanical (steam powered) pump as a closed-system in combination with an F&T trap, a double duty type combination device, or a separate open system pump/receiver either mechanical or electric.

3. When the system is operating smoothly and efficiently, look for more ways to increase efficiency by auditing different areas of the generation, distribution, heat transfer, and condensate handling systems periodically and look for opportunities to design and use heat recovery systems. At a minimum, test steam traps once a year for proper operation, but to eliminate the +/- 6 months of lag time between discovery of failed traps at that one moment in time plus the time it takes to arrange and actually repair or replace the steam trap, consider a wireless steam trap monitoring system, at least for the most process-important or highest pressure steam traps that will have the largest steam loss where discovery of failure is within minutes, the system can self-generate a work order, and the repair can be done quickly. One such system utilizes either ISA100 or WirelessHART mesh networks reporting to a measurement, monitoring, and reporting software system designed to manage the system effectively.

2. If you don’t really understand the thermodynamics, proper piping techniques, and potential problems that may occur in your steam system, don’t experiment. Contact someone who has thorough knowledge of steam systems before making that first change.

1. If you do understand your steam heat transfer system, have never instructed someone to “just change out the steam trap, it must be the blame for my system not working correctly since I don’t really know what it does,” then you may be numbered in that new group: “Steam system practitioner, the making of another Prima Donna”.

List courtesy of Steve Huffman, VP of Sales and Marketing, Mead O'Brien.

Labels:

Arkansas,

Armstrong,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

Southern Illinois,

Steam Systems,

Steve Huffman,

Western Kentucky

Selecting the Proper ASCO Solenoid Valve

This catalog is designed to make it easier to select and order the right valve for your application from ASCO. It provides very handy tables of part numbers, port configurations, sizes, and materials.

Download the PDF version here and keep available when when specifying ASCO solenoid valves.

Download the PDF version here and keep available when when specifying ASCO solenoid valves.

Labels:

Arkansas,

ASCO,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

Solenoid Valve,

Southern Illinois,

Western Kentucky

The Armstrong SAGE UMT™ Wireless Hand-held Steam Trap Testing Tool

The next-level addition to the most comprehensive and advanced steam trap management platform in the industry has arrived. Introducing SAGE UMT™. Wireless, water resistant, dust proof, rugged, accurate, consistent. SAGE UMT's performance eliminates human error and sets a new standard for trap testing.

It's easier and faster to test traps and instantly, send data to mobile devices and the cloud. And with 10 plus hours of battery life, SAGE UMT™ can go all day long.

SAGE UMT™ comes complete with charger, carrying case, bolster, ergonomic handle design and rubberized grip. All you have to add is the hardhat, the mobile device, and a human.

Armstrong's SAGE UMT™, used in conjunction with SAGE® Smart Steam System Management

Armstrong's SAGE UMT™, used in conjunction with SAGE® Smart Steam System Management platform, is the most comprehensive and advanced trap management program in the industry.

- Detects traps in good, cold and blow-through condition

- Piezoelectric acoustic sensor, developed and tuned specifically for the unique conditions found in steam traps

- Non-contact infrared temperature sensor

- RFID technology significantly reduces the time required to locate and identify traps

- SAGE UMT™ works seamlessly with SAGE Mobile and SAGE Smart Utility System Management platform

- Data is uploaded to the cloud by SAGE for secure storage and automated backups

- Customers own their own data

- Use SAGE UMT™ for 10 hours or more before recharging; charge is restored to 90% within 2.5 hours

- Easy-to-hold, ergonomic handle with rubberized ribbed grip

- Convenient holster holds SAGE UMT™ securely; configure for right- or left-hand use

- Lifetime upgrades for SAGE UMT™ firmware at no charge

Labels:

Arkansas,

Armstrong,

audit,

energy,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

SAGE,

Southern Illinois,

steam trap,

Western Kentucky

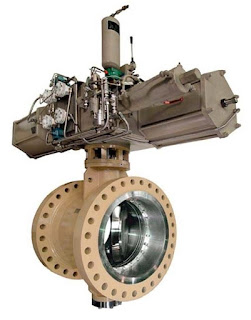

Metal Seated High Performance Butterfly Valves

|

| Metso Neles BW Series |

DOWNLOAD THE BW SERIES SPECIFICATION SHEET HERE

The BW provides extended operational life in control, tight shut-off and critical applications such as high cycle, high temperature, cryogenic, oxygen and abrasive applications, etc. Rating from ASME 900 to 2500 makes the BW a sound control or shut-off valve in severe service applications.

Excellent on-off capabilities

- Uniquely functioning full metal seat design assures tightness over long time periods.

- Contact between disc and seat is mechanically induced and does not rely on assistance from differential pressure.

- Long term tightness is maintained even in high cycle rate services. Tightness in not compromised by large thermal cycling either.

- Low friction and excellent wear resistance.

- Lowered operational torque reduces actuator size

- Heavy-duty stem and ingenious bearings design extends service life and is insensitive to thermal cycles and impurities.

- Good controllability via smoothly rising installed characteristic curve at both very small openings and nearly full Cv positions. Series BW provides very wide rangeability in fairly low pressure drop services.

- Good dynamic stability in both flow directions.

- Available with a variety of actuators, positioners and accessories for single source responsibility. Mounting face according to ISO 5211.

- Abrasion resistant construction

- Solid, sturdy all metal seat design is based on metal-to- metal contact. No resilient parts are needed for seating.

Low emissions

- The live loaded gland packing is located right after the outer bearing maximizing the tightness. The emissions are well below the international standards.

- Furthermore, there are no resilient parts exposed to the medium.

- Differential pressure/temperature ratings in accordance with ASME B16.34.

- Extremely wide temperature range up to +1150°C / +2100 °F.

- Low cost of ownership

- Extremely high cycle life minimizes the need for maintenance, and increases Mean Time Between Failure (MTBF) value.

- Interchangeable seat can be replaced without disassembling the disc and shaft. Seat replacement does not require any adjustment or special tools.

- Certified emission and fire safe performance

- Emission certified according to industry standard, ISO 15848-1 class B in shut-off applications.

- Fire safe certification according to API 607, 6th edition

Certified safety performance

- SIL certification to meet IEC61508 requirements

- Capable to SIL 3 level

Applications

The BW series butterfly valve is suitable for the following industries and applications.

- Chemical Process: Tail gas, waste water, Flue gas, styrene, acrylic acid

- Refinery: Flammable media, process, gas

- Off-shore: Flammable media, process, gas

- Steel: Gas and crude gas

- Gas: Natural gas, sour gas

- Nuclear power: Steam, gas, water

- Conventional power: Steam, gas, water

For more information about the Neles BW Series, contact Mead O'Brien at (800) 892-2769 or visit their web site at https://meadobrien.com.

Intumescent "FR Shells" Provide Passive Fire Protection for Electric Valve Actuators

According to Wikipedia, an intumescent "is a substance that swells as a result of heat exposure, thus increasing in volume and decreasing in density. Intumescents are typically used in passive fire protection."

Intumescents play a valuable role in electric valve actuation. Removable intumescent fireproof coatings referred to as "FR Shells" (from actuator manufacturer Limitorque) provide simple fireproof protection to an electric actuator quickly and easily. The construction is reinforced with wire to enhance its performance and protection of the valve actuator for at least 30 minutes against a hydrocarbon fire. Based on this design capability, the valve actuator will not require being sent to the OEM for replacement coatings in the event of a fire. The intumescent coating can be installed on-site for existing actuators without any modification. The design of the intumescent coating comes in sectional forms and is assembled/secured with external fixing screws supplied with the FR Shells. The FR Shells are protected against harmful UV rays with an approved paint.

How They Work

The intumescent coating maintains itself in a solid state until contact is made with fire. Once contact is made with flame, the intumescent coating (coating surface) is converted into a highly viscous liquid. A reaction combining combustion of the epoxy and gas liberation then takes place resulting in an expansion up to eight times the initial thickness of the original coating. The result is a low-density, carbonaceous insulation char. The layer of char absorbs most of the heat generated by the fire, thus protecting the actuator and its internal parts from exposure to the extreme temperatures of a hydrocarbon fire.

The intumescent coating maintains itself in a solid state until contact is made with fire. Once contact is made with flame, the intumescent coating (coating surface) is converted into a highly viscous liquid. A reaction combining combustion of the epoxy and gas liberation then takes place resulting in an expansion up to eight times the initial thickness of the original coating. The result is a low-density, carbonaceous insulation char. The layer of char absorbs most of the heat generated by the fire, thus protecting the actuator and its internal parts from exposure to the extreme temperatures of a hydrocarbon fire.

Advantages

Intumescents play a valuable role in electric valve actuation. Removable intumescent fireproof coatings referred to as "FR Shells" (from actuator manufacturer Limitorque) provide simple fireproof protection to an electric actuator quickly and easily. The construction is reinforced with wire to enhance its performance and protection of the valve actuator for at least 30 minutes against a hydrocarbon fire. Based on this design capability, the valve actuator will not require being sent to the OEM for replacement coatings in the event of a fire. The intumescent coating can be installed on-site for existing actuators without any modification. The design of the intumescent coating comes in sectional forms and is assembled/secured with external fixing screws supplied with the FR Shells. The FR Shells are protected against harmful UV rays with an approved paint.

How They Work

The intumescent coating maintains itself in a solid state until contact is made with fire. Once contact is made with flame, the intumescent coating (coating surface) is converted into a highly viscous liquid. A reaction combining combustion of the epoxy and gas liberation then takes place resulting in an expansion up to eight times the initial thickness of the original coating. The result is a low-density, carbonaceous insulation char. The layer of char absorbs most of the heat generated by the fire, thus protecting the actuator and its internal parts from exposure to the extreme temperatures of a hydrocarbon fire.

The intumescent coating maintains itself in a solid state until contact is made with fire. Once contact is made with flame, the intumescent coating (coating surface) is converted into a highly viscous liquid. A reaction combining combustion of the epoxy and gas liberation then takes place resulting in an expansion up to eight times the initial thickness of the original coating. The result is a low-density, carbonaceous insulation char. The layer of char absorbs most of the heat generated by the fire, thus protecting the actuator and its internal parts from exposure to the extreme temperatures of a hydrocarbon fire.Advantages

- Lightweight design

- Can be installed on existing actuator

- No modification is required of the actuator.

- Easy installation and removal

- No special tools are required.

- Installation space is not required.

- Can be re-used in the event of actuator replacement

- If a part fails (e.g., motor), re-coating is not required.

- Excellent finishes in decorative grade

- Separate storing of intumescent coating is possible, against damage during installation of valve/actuator.

Why Measuring Differential Pressure Across a Filter or Strainer is Important

|

| Differential pressure gauge. (Ashcroft) |

Filters and strainers commonly are positioned to capture solids and particulates. The filter will obstruct the flow through the pipe lowering the pressure on the downstream side. These effects may vary depending on the filters construction. Filter media is the material that removes impurities. The smaller the pores, the larger the friction. Higher friction means greater pressure drop. Contaminants or particulates that build up in the filter will reduce media flow. As the filter becomes clogged, the downstream pressure drops. This results in an increased differential pressure, also referred to as the Delta-P. Saturated filters may also begin to shed

|

| Differential pressure switch. (Ashcroft) |

|

| Differential pressure transmitter. (Ashcroft) |

When specifying a differential pressure instrument there are two important factors to consider. The first is the DP range, which is based upon the most difference in pressure that the restriction is likely to produce. The second is the instruments ability to contain the static pressure, which is simply the pressure in the line while the differential pressure remains the same. A higher line pressure may require an instrument rated for higher static pressure.

Mead O'Brien

https://meadobrien.com

(800) 892-2769

Labels:

Arkansas,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

Southern Illinois,

Western Kentucky

NACE Standards - Measuring the Pressure of Sour Gas and Crude

In 1943 a group of corrosion engineers working in the pipeline industry formed the National Association of Corrosion Engineers with the goal of "protecting people, assets, and the environment from corrosion”. In the 1960s, they commenced development of control standards to define appropriate materials for a wide variety of corrosive applications, including oil and gas production and refinery facilities. In 1993, the organization was renamed “NACE International”.

In 1943 a group of corrosion engineers working in the pipeline industry formed the National Association of Corrosion Engineers with the goal of "protecting people, assets, and the environment from corrosion”. In the 1960s, they commenced development of control standards to define appropriate materials for a wide variety of corrosive applications, including oil and gas production and refinery facilities. In 1993, the organization was renamed “NACE International”.Today, NACE offers over 150 standards that address metal corrosion in a vast number of applications ranging from exposed metal structures to corrosion resistant coatings on railroad cars.

The following NACE Measuring Pressure of Sour Gas and Crude White Paper (courtesy of Ashcroft) discusses NACE standards that specifically address corrosion resulting from expo- sure to sour gas or sour crude.

You can download the entire NACE Standards Sour Gas and Crude White Paper here, or review it in the embedded document below.

For more information, contact Mead O'Brien at (800) 892-2769 or visit their web site at https://meadobrien.com.

Labels:

Arkansas,

Ashcroft,

Indiana,

Iowa,

Kansas,

Missouri,

NACE,

Nebraska,

Oklahoma,

pressure measurement,

Southern Illinois,

Western Kentucky

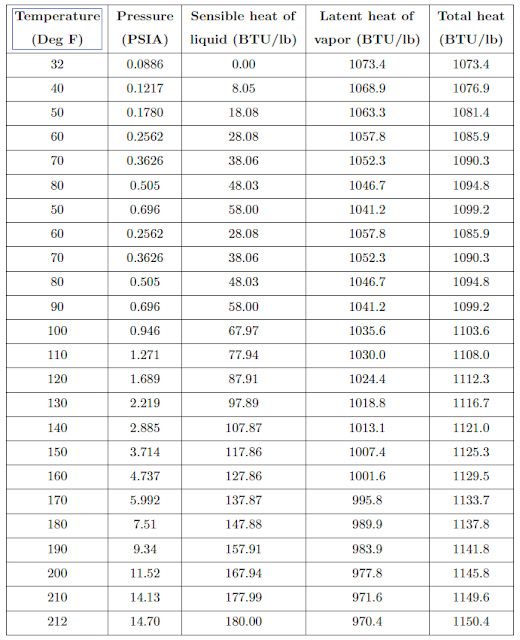

Saturated Steam Table

A saturated steam table shows temperatures and pressures for water at the liquid/vapor transition (i.e. points lying along the liquid/vapor interface shown in a phase change diagram), as well as enthalpy values for the water and steam under those conditions. The sensible heat of water is the amount of thermal energy per pound necessary to raise water’s temperature from the freezing point to the boiling point. The latent heat of vapor is the amount of energy per pound necessary to convert water (liquid) into steam (vapor). The total heat is the enthalpy of steam (thermal energy per pound) between the listed condition in the table and the freezing temperature of water.

By definition a saturated steam table does not describe steam at temperatures greater than the boiling point. For such purposes, a superheated steam table is necessary.

Mead O'Brien

https://meadobrien.com

(800) 892-2769

By definition a saturated steam table does not describe steam at temperatures greater than the boiling point. For such purposes, a superheated steam table is necessary.

Mead O'Brien

https://meadobrien.com

(800) 892-2769

Saturated Steam Table

Reprinted from "Lessons In Industrial Instrumentation" by Tony R. Kuphaldt – under the terms and conditions of the Creative Commons Attribution 4.0 International Public License.

Data for this saturated steam table was taken from Thermal Properties of Saturated and Superheated Steam by Lionel Marks and Harvey Davis, published in 1920 by Longmans, Green, and Company.

Data for this saturated steam table was taken from Thermal Properties of Saturated and Superheated Steam by Lionel Marks and Harvey Davis, published in 1920 by Longmans, Green, and Company.

Labels:

Arkansas,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

process heat,

Saturated Steam Table,

Southern Illinois,

steam,

Western Kentucky

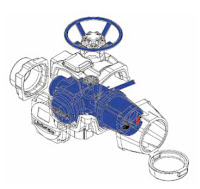

Triple Offset Butterfly Valve Operation and Features

Triple offset butterfly valves provide superior performance, increased durability, reliability and lower ownership cost than traditional valves.

Triple offset butterfly valves are recognized for excellent flow control characteristics, zero leakage, and reliability. They are designed for superior performance in high pressure and extreme temperature applications. Their design includes metal seats which are inherently fire safe. They maintain their zero leakage seal even in extreme operating conditions. Finally, triple offset butterfly valves typically weigh less than similar sized valves, allowing for easier installation and maintenance.

TRICENTRIC®, the leading manufacturer of triple offset valves, engineer their products to meet stringent industry requirements and offer cost savings to the end user through improved life cycle costs, reducing emissions, reducing downtime and requiring lower maintenance costs.

Triple offset butterfly valves have a huge installed base and a commonly used in a range of industries including:

(800) 892-2769

Triple offset butterfly valves are recognized for excellent flow control characteristics, zero leakage, and reliability. They are designed for superior performance in high pressure and extreme temperature applications. Their design includes metal seats which are inherently fire safe. They maintain their zero leakage seal even in extreme operating conditions. Finally, triple offset butterfly valves typically weigh less than similar sized valves, allowing for easier installation and maintenance.

TRICENTRIC®, the leading manufacturer of triple offset valves, engineer their products to meet stringent industry requirements and offer cost savings to the end user through improved life cycle costs, reducing emissions, reducing downtime and requiring lower maintenance costs.

Triple offset butterfly valves have a huge installed base and a commonly used in a range of industries including:

- Aerospace

- Conventional power

- Nuclear power

- Oil & gas / refining

- Desalination

- Chemical processing

- Pulp & paper mills

- Military

(800) 892-2769

Hot Water for Industry from Mead O'Brien

Mead O'Brien, in partnership with Armstrong International, delivers accuracy, simplicity and unparalleled performance in instantaneous hot water generation, distribution and precision temperature control.

From a single product, to a complete fully integrated system, Mead O'Brien can provide a hot water solution to meet your most demanding needs.

Products include standard and application-customized steam/water instantaneous water heaters for any process application requiring very specific temperatures, from chilled water to temperatures as high as 212°F (100°C), as well as Mixing Centers, VFD Pump Assemblies, Hot & Cold Water Hose Stations, Gas-Fired Water Heaters, and Digital Control Valves.

https://meadobrien.com

(800) 892-2769

From a single product, to a complete fully integrated system, Mead O'Brien can provide a hot water solution to meet your most demanding needs.

Products include standard and application-customized steam/water instantaneous water heaters for any process application requiring very specific temperatures, from chilled water to temperatures as high as 212°F (100°C), as well as Mixing Centers, VFD Pump Assemblies, Hot & Cold Water Hose Stations, Gas-Fired Water Heaters, and Digital Control Valves.

https://meadobrien.com

(800) 892-2769

Industrial Thermowells: Sometimes Taken for Granted, but Critically Important

|

| Thermowells come in a wide variety of shapes, materials, and sizes. (Courtesy of Ashcroft) |

Thermowells are critically important for installations where the temperature element (RTD, thermocouple, etc.) must be replaceable without de-pressurizing the process.

Thermowells may be made out of any material that is thermally conductive, pressure-tight, and not chemically reactive with the process. Most thermowells are formed out of either metal (stainless steel or other alloy) or ceramic materials.

A simple diagram showing a thermowell in use with a temperature sensor (RTD) is shown here:

|

| Typical RTD thermowell installation. |

As useful as thermowells are, they are not without their caveats. All thermowells, no matter how well they may be installed, increase the first-order time lag of the temperature sensor by virtue of their mass and specific heat value. It should be intuitively obvious that a few pounds of metal will not heat up and cool down as fast as a few ounces’ worth of RTD or thermocouple, and therefore the addition of a thermowell to the sensing element will decrease the responsiveness of any temperature- sensing element. What is not so obvious is that such time lags, if severe enough, may compromise the stability of feedback control. A control system receiving a “delayed” temperature measurement will not see the live temperature of the process in real time due to this lag.

For more information on thermowells, contact Mead O'Brien by visiting https://meadobrien.com or by calling (800) 892-2769.

Five Important Criteria in Applying Pressure Gauges

|

| Process pressure gauge. (Ashcroft) |

While there are millions of possible combinations of shapes, sizes, options and materials, pressure gauges all share the five following application criteria, required for safe use and long product life.

|

| Diaphragm seal. (Ashcroft) |

1 - Process Media Properties: Media that is corrosive, sludgy, or that can solidify is a potential problem for pressure gauges. In non-corrosive, non-clogging media applications, a direct connection without intermediate protection can be applied. For process media that could potentially clog or chemically affect the gauge's wetted parts, a diaphragm seal should be used.

2 - Process Media Temperature: Very hot media, such as steam or hot water, can elevate the gauge's internal temperature leading to failure or an unsafe condition. For high temperature applications, the use of a "pigtail siphon" or diaphragm seal is recommended. Siphons act as a heat sink and lower the exposure temperature. Diaphragm seals isolate the gauge from the higher temperatures.

|

| Pigtail siphon. |

|

| Snubber |

5 - Mounting: Pressure gauges are standardly available with bottom (radial) and back connections. NPT (National Pipe Thread Taper) threaded connections are generally the standard. Many other process connections are available though, such as straight threads, metric threads, and specialized fittings. Make sure you know how the gauge is being connected. When mounting, pressure gauges should be almost always be mounted upright.

For more information about pressure gauges, contact Mead O'Brien by visiting https://meadobrien.com or by calling (800) 892-2769.

Labels:

Arkansas,

Ashcroft,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

pressure gauges,

Southern Illinois,

Western Kentucky

Limitorque Fluid Power Systems (LFPS)

Limitorque Fluid Power Systems is a group of modular scotch yoke fluid power actuators designed to deliver maximum torque with the lowest possible displacement and overall size. These heavy-duty, fluid-powered valve actuators and control systems are design primarily for the oil and gas industry. The group is categorized into three major sub-groups:

Mead O'Brien

www.meadobrien.com

(800) 892-2769

- Gas Powered Actuators - The Limitorque LDG direct gas actuator is designed to operate on high pressure pneumatic supply, including pipeline gases, nitrogen and any other equivalent high pressure source.

- Hydraulic Actuators - LHS and LHH are Limitorque’s range of hydraulic, quarter-turn, scotch yoke actuators. Designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry LHS and LHH are suitable for on/off and modulating control of all quarter-turn valves.

- Pneumatic Actuators - Limitorque’s LPS and LPC are pneumatic quarter turn scotch yoke actuators, featuring a robust design suitable for heavy duty services, and among the longest design lifespans and maintenance intervals in the industry.

Mead O'Brien

www.meadobrien.com

(800) 892-2769

Industrial Boiler and Burner Limit Control Switches

|

| Ashcroft Limit Control Switch |

Read the embedded document below, or you can download your own PDF copy of "Industrial Boiler and Burner Limit Control Switches" from the Mead O'Brien website here.

Measuring the Flow of Vaporized Liquid Natural Gas

|

| Veris Accelabar installed on vaporized liquid natural gas line. |

A liquid natural gas plant in the Midwest needed to measure gas flow to heaters that vaporize LNG to gaseous natural gas for use during peak periods in the winter season. The company stores LNG in two 12,000,000-gallon tanks and uses gas-fired heaters to vaporize it as required to meet customer demand. For most of the year demand is low (1,000 SCFH); however, during the coldest winter months gas consumption jumps to 60,000 standard cubic feet per hour (SCFH) in a 3” sch 40 line at 80 psig/70° F.

Problem

The plant must account for the gas usage over the entire range as it is part of the operating cost during LNG vaporization, as well as when it is used for plant heating. The customer could not find one meter to accommodate the entire range accurately. The plant had attempted to measure the flow rate with a Roots turbine meter sized for the maximum flow rate, but could not get accurate flow readings at the low end of the measurement range, making it impossible to determine actual usage during the off-peak periods. In addition to accuracy limitations, turbine meters have moving parts that wear and require expensive maintenance. The customer’s operating cost was estimated and charged against the bottom line. In addition, as you can see from the photo, there was no straight run available which hindered a conventional meter’s ability to perform accurately.

|

| Accelabar |

Solution

A Model AF 3” 150-H-M Accelabar was installed immediately downstream of a pipe reduction, control valve and pressure regulator. The Accelabar had two Foxboro IDP50 high accuracy DP transmitters directly mounted to the top of the Accelabar sensor. Stacked outputs were required to accommodate the wide turndown in DP of 308.2” w.c. at max and 0.08” w.c. at min.

Results

The Accelabar performed as advertised with ±0.75% accuracy over the entire range of 1,000 to 60,000 SCFH—a flow turndown of 60:1. Because the Accelabar and transmitters have no moving parts to wear or seize, maintenance is minimal. The LNG supplier has found that the flow metering system is user friendly and easy to operate, especially since DP flow measurement is one of the most easily understood of any flow measurement technology available. To the LNG provider, this translates into improved material accountability and lower operating costs to increase profitability.

Reprinted with permission by Veris, a division of Armstrong International.

Configuration and Setting the Schneider Electric / Foxboro IMT30A Magnetic Flow Signal Converter

This video below provides instruction on setting the Schneider Electric / Foxboro Model IMT30A.

The electromagnetic signal converter IMT30A is a used for measuring volumetric flow in various kinds of applications that can be found in the water industry and food and beverage processing. The IMT30A can be used together with Foxboro flow sensors 8400A, 8500A, 9500A, 9600A and 9700A with outputs representing measured values for flow, mass and conductivity.

Industries

(800) 892-2769

The electromagnetic signal converter IMT30A is a used for measuring volumetric flow in various kinds of applications that can be found in the water industry and food and beverage processing. The IMT30A can be used together with Foxboro flow sensors 8400A, 8500A, 9500A, 9600A and 9700A with outputs representing measured values for flow, mass and conductivity.

Industries

- Water & Wastewater

- Food & Beverage

- Heating, Ventilation & Air Conditioning (HVAC)

- Agriculture

- Steel

- Water and wastewater treatment Water distribution network Irrigation installation

- Water abstraction

- CIP cleaning stations

(800) 892-2769

Limitorque Fluid Power Systems (LFPS)

Limitorque Fluid Power Systems (LFPS) is the Flowserve Limitorque division that builds fluid power actuators, specifically pneumatic, gas, and hydraulic scotch yoke design cylinder valve actuators. These are used on larger, higher torque requirement valves primarily applied in the oil and gas industries.

For more information on Limitorque Fluid Power Systems, contact Mead O'Brien by visiting https://meadobrien.com or calling (800) 892-2769

GAS POWERED ACTUATORS

The Limitorque LDG direct gas actuator is designed to operate on high pressure pneumatic supply, including pipeline gases, nitrogen and any other equivalent high pressure source. Based on Limitorque’s high efficiency scotch-yoke modules, the self-contained system includes both the gas powered actuation unit and the high pressure gas control circuit. This makes it a robust and efficient way of providing reliable pipeline valve automation, even when no external motive power supplies are present. Limitorque’s advanced design criteria together with the full pressure rated controls allow higher torque output within a smaller dimensional envelope, thus reducing gas use and exhaust, and limiting pipeline product waste and environmental impact.HYDRAULIC ACTUATORS

LHS and LHH are Limitorque’s range of hydraulic, quarter-turn, scotch yoke actuators. Designed to meet or exceed the most current and stringent safety and reliability standards for application in the oil and gas industry LHS and LHH are suitable for on/off and modulating control of all quarter-turn valves. Limitorque scotch yoke actuators deliver reliable torque ranges up to 300 kNm (221 268 ft-lb) in a low displacement, compact dimensional envelope with a maximum allowable working pressure (MAWP) of 207 barg (3000 psig) for the LHS series and 345 barg (5000 psig) for the LHH series.PNEUMATIC ACTUATORS

Limitorque’s LPS and LPC are pneumatic quarter turn scotch yoke actuators, featuring a robust design suitable for heavy duty services, and among the longest design lifespans and maintenance intervals in the industry. Limitorque’s high torque LPS (up to 500000 Nm / 369,000 ft-lbs) and compact LPC (up to 5500 Nm / 4056 ft-lb) are the actuators of choice for effective on/off, modulating and control applications of quarter-turn valves in all general and protective services, in the most severe environments.For more information on Limitorque Fluid Power Systems, contact Mead O'Brien by visiting https://meadobrien.com or calling (800) 892-2769

Why Is Monitoring the Amount of Moisture in a Steam System So Critically Important?

Wet steam is a costly problem across many industries. It causes product quality issues with batch rejection, wet packs and wet loads in sterilizers. Wet culinary steam can make food grade quality of product impossible. Carbon dioxide in a system with wet steam creates carbonic acid that damages pipes. A slug of water causes water hammering, which is destructive and can be deadly. Wet steam causes many flowmeters to be inaccurate, so that if you buy steam from a third party, you may be paying for water rather than steam. Water abrades like sand in a steam pipe and will erode pipes, elbows, valves and other components. Wet steam reduces heat transfer. Wet steam can damage turbines. And wet steam causes thermal stress as condensate cools down.

In fact, steam quality typically refers to the amount of water in the steam, which is also known as dryness fraction. Saturated steam is a mixture of steam and water. The water is often in the form of un-vaporized micro droplets. Dryness fraction is a ratio. The mass of the steam to the mass of the biphasic mixture of water and steam. Part of the difficulty in measuring the steam dryness fraction is that steam systems are dynamic. The steams is moving through the components and conditions change second-by-second. Within this complex system there are many things that contribute to water in the steam. For example, the bursting bubbles from the surface of the boiling water expels small droplets into the flow of steam. Or if there is a sudden increase in demand for steam that reduces pressure above the water, lowering the boiling point and increasing the violence of bubbling. This is sometimes called priming or carryover. Other forms of carryover include water in the system, because the water level in the boiler is too high. Or high concentrations of impurities in the boiler water that reduce the surface tension and so increase the agitation of the water surface. Impurities can also cause the formation of a stable foam above the water surface. This foam causes slugs of water to be intermittently discharged from the boiler along with the steam. Even poor insulation in pipes and valves leads to water in the steam as heat is lost and steam condenses. A steam trap might fail closed, particularly at the bottom of a separator, increasing the amount of condensate in the pipes. The design of steam pipe work and steam traps may be inadequate to handle condensate, or a steam separator may be defective.

Any of these things individually or in combination can cause a problem with dryness fraction. Monitoring the dryness fraction of steam has long been a manual process, time-consuming, inconsistent, unreliable, and presents inherent safety and accuracy risks. Control of your steam quality depends on having consistent, accurate, timely information, and that's where the Armstrong Steam QM-1 comes in.

The Armstrong steam quality monitor steam QM1 provides you with data logging and remote monitoring capabilities. The Steam QM-1 monitors and measures dryness fraction and alerts you of steam quality problems. The video below explains how.

With monitoring by the Steam QM-1 you can:

In fact, steam quality typically refers to the amount of water in the steam, which is also known as dryness fraction. Saturated steam is a mixture of steam and water. The water is often in the form of un-vaporized micro droplets. Dryness fraction is a ratio. The mass of the steam to the mass of the biphasic mixture of water and steam. Part of the difficulty in measuring the steam dryness fraction is that steam systems are dynamic. The steams is moving through the components and conditions change second-by-second. Within this complex system there are many things that contribute to water in the steam. For example, the bursting bubbles from the surface of the boiling water expels small droplets into the flow of steam. Or if there is a sudden increase in demand for steam that reduces pressure above the water, lowering the boiling point and increasing the violence of bubbling. This is sometimes called priming or carryover. Other forms of carryover include water in the system, because the water level in the boiler is too high. Or high concentrations of impurities in the boiler water that reduce the surface tension and so increase the agitation of the water surface. Impurities can also cause the formation of a stable foam above the water surface. This foam causes slugs of water to be intermittently discharged from the boiler along with the steam. Even poor insulation in pipes and valves leads to water in the steam as heat is lost and steam condenses. A steam trap might fail closed, particularly at the bottom of a separator, increasing the amount of condensate in the pipes. The design of steam pipe work and steam traps may be inadequate to handle condensate, or a steam separator may be defective.

|

| Armstrong Steam QM-1 |

Any of these things individually or in combination can cause a problem with dryness fraction. Monitoring the dryness fraction of steam has long been a manual process, time-consuming, inconsistent, unreliable, and presents inherent safety and accuracy risks. Control of your steam quality depends on having consistent, accurate, timely information, and that's where the Armstrong Steam QM-1 comes in.

The Armstrong steam quality monitor steam QM1 provides you with data logging and remote monitoring capabilities. The Steam QM-1 monitors and measures dryness fraction and alerts you of steam quality problems. The video below explains how.

With monitoring by the Steam QM-1 you can:

- Manage process quality when injecting steam

- Ensure foodgrade quality of steam when producing culinary steam

- Check dryness of outsource steam

- Avoid water hammer

- Oversee traps and separators effectiveness

- Monitor boiler carryover

- Avoid erosion in valves regulators etc

- Protect turbine low pressure saturated steam stages

Labels:

Arkansas,

Armstrong,

Indiana,

Iowa,

Kansas,

Missouri,

moisture,

Nebraska,

Oklahoma,

Southern Illinois,

Steam QM-1,

steam system,

Western Kentucky

Metso Neles Flow Control Solutions: Valves, Actuation, and Automation

Neles Controls, a unit of Metso Automation, is a manufacturer of high quality rotary control valves,

Neles Controls, a unit of Metso Automation, is a manufacturer of high quality rotary control valves, on/off valves, actuators, positioners, emergency shutdown valves (ESD), digital valve position

control products and severe service specialty valve products.

Their product mix includes:

- Control Valves

- Globe Control Valves

- On-Off Valves

- ESD Valves, Engineered Valves

- Smart Positioners

- Analog Positioners

- Pneumatic Actuators

- Electric Actuators

- Limit Switches

Below is their comprehensive Flow Control Solutions catalog. You may review the embedded document, or download a PDF version of the Neles Flow Control Solutions here.

Mead O'Brien: Total Process Control Solutions Provider

As experts in valve automation, process instrumentation, steam systems and hot water systems, Mead O'Brien provides solutions to industrial companies in Missouri, Kansas, Nebraska, Iowa, Oklahoma, Arkansas, Texas Panhandle, Southern Illinois, Western Kentucky, and Southwest Indiana.

Specializing in Power, Refining, Chemical, Food & Beverage, Oil & Gas, Heavy Industrial, Water & Wastewater, and HVAC, Mead O’Brien provides it's customers outstanding products, superior customer service, a team of highly skilled technicians, and decades of application experience.

These assets, in combination with their track record of successful outcomes and loyal customer base, positions Mead O'Brien as the perfect partner for all your process control equipment needs.

Give Mead O'Brien a call today.

These assets, in combination with their track record of successful outcomes and loyal customer base, positions Mead O'Brien as the perfect partner for all your process control equipment needs.

Give Mead O'Brien a call today.

https://meadobrien.com

(800) 892-2769

(800) 892-2769

Subscribe to:

Posts (Atom)