May your holidays glitter with unforgettable moments of happiness, laughter, and good cheer.

Providing problem solving and educational information for topics related to industrial steam, hot water systems, industrial valves, valve automation, HVAC, and process automation. Have a question? Give us a call at (800) 892-2769 | www.meadobrien.com

Season's Greetings from Mead O'Brien

A Peek Inside an Industrial Centrifugal Separator

A centrifugal separator is a piece of equipment that uses centrifugal force, the force of gravity, and inertia to separate two or more materials. Centrifugal separators work by spinning the material in a chamber at high speed which causes the heavier materials to settle out separately from the lighter materials.

A centrifugal separator is a piece of equipment that uses centrifugal force, the force of gravity, and inertia to separate two or more materials. Centrifugal separators work by spinning the material in a chamber at high speed which causes the heavier materials to settle out separately from the lighter materials.Upon entering the spinning chamber of a centrifugal separator, the spinning force affect materials differently. Heavier materials are more affected by gravity, while lighter materials are affected by inertia. As the materials separate, they are collected in various mechanical or physical ways, such as filtering and screening.

Gases can be purified through the spinning process to remove particulate matter and moisture. The pure gas gas is then be collected as it escapes through the top of the centrifugal separator. Similarly liquids of different weights and viscosities are divided into various chambers in the separator as it moves along.

The Anderson Hi-eF™ Centrifugal Separators operate on a patented two-stage principle of separation that employs carefully controlled flow guiding the entrainment laden vapor through a series of vanes and baffles. Each component of the separating element is designed to obtain maximum separating efficiency. Briefly, in the first stage of the separation, impingement against a baffle removes the larger droplets of entrainment. In the second stage of separation, the separator removes the fine mist entrainment by utilizing centrifugal scrubbing action through a uniquely designed contact element. In each stage, the gas medium and the separated liquid are carefully and continuously guided for maximum efficiency. The separators are designed to handle large volume flow of a broad range of fluids. Self-cleaning and engineered without filters or moving parts, the separators are free from maintenance and repair. For more information visit http://www.meadobrien.com or call (800) 892-2769.

Watch this video to see an animation of what happens inside the centrifugal separator.

The Application of Limit Switches on Automated Industrial Valves

|

| Limit switch with position indicator. |

Employed in a wide range of industrial applications and operating conditions, limit switches

|

| Automated valve assembly including actuator and limit switch. |

Valves, devices used for controlling flow, are motion based. The movable portions of valve trim create some degree of obstruction to media flow, providing regulation of the passage of the media through the valve. It is the movement of critical valve trim elements that limit switches are used to indicate or control. The movable valve trim elements commonly connect to a shaft or other linkage extending to the exterior of the valve body. Mounting electric, hydraulic, or pneumatic actuators to the shaft or linkage provides the operator a means to drive the mechanical connection, changing the orientation or position of the valve trim and regulating the media flow. Because of its positive connection to the valve trim, the position of the shaft or linkage is analogous to the trim position and can be used to indicate what is commonly referred to as “valve position”. Limit switches are easily applied to the valve shaft or linkage in a manner that can provide information or direct functional response to certain changes in valve position.

In industrial valve terms, a limit switch is a device containing one or more magnetic or electrical switches, operated by the rotational or linear movement of the valve.

What are basic informational elements that can be relayed to the control system by limit switches? Operators of an industrial process, for reasons of efficiency, safety, or coordination with other process steps, may need answers to the following basic questions about a process control valve:

Employing a properly configured valve automation package, with limit switches delivering valve status or position information to your control system, can yield operational and safety benefits for the life of the unit. Good advice is to consult with a valve automation specialist for effective recommendations on configuring your valve automation accessories to maximize the level of information and control.

In industrial valve terms, a limit switch is a device containing one or more magnetic or electrical switches, operated by the rotational or linear movement of the valve.

What are basic informational elements that can be relayed to the control system by limit switches? Operators of an industrial process, for reasons of efficiency, safety, or coordination with other process steps, may need answers to the following basic questions about a process control valve:

- Is the valve open?

- Is the valve closed?

- Is the valve opening position greater than “X”?

- Has the valve actuator properly positioned the valve at or beyond a certain position?

- Has the valve actuator driven the valve mechanism beyond its normal travel limits?

- Is the actuator functioning or failing?

Partial or complete answers to these and other questions, in the form of electrical signals relayed by the limit switch, can serve as confirmation that a control system command has been executed. Such a confirmation signal can be used to trigger the start of the next action in a sequence of process steps or any of countless other useful monitoring and control operations.

Applying limit switches to industrial valve applications should include consideration of:

Applying limit switches to industrial valve applications should include consideration of:

- Information Points – Determine what indications are necessary or useful for the effective control and monitoring of valve operation. What, as an actual or virtual operator, do you want to know about the real time operational status of a valve that is remotely located. Schedule the information points in operational terms, not electrical switch terms.

- Contacts – Plan and layout a schedule of logical switches that will provide the information the operator needs. You may not need a separate switch for each information point. In some cases, it may be possible to derive needed information by using logical combinations of switches utilized for other discrete functions.

- Environment – Accommodate the local conditions and hazards where the switch is installed with a properly rated enclosure.

- Signal – The switch rating for current and voltage must meet or exceed those of the signal being transmitted.

- Duty Cycle – The cycling frequency must be considered when specifying the type of switch employed. Every switch design has a limited cycle life. Make sure your selection matches the intended operating frequency for the process.

- Auxiliary Outputs – These are additional contact sets that share the actuation of the primary switch. They are used to transmit additional signals with specifications differing from the primary signal.

- Other Actuator Accessories – Limit switches are often integrated into an accessory unit with other actuator accessories, most of which are related to valve position. A visual local indication of valve position is a common example.

Switches and indicators of valve position can usually be provided as part of a complete valve actuation package, provided by the valve manufacturer or a third party. It is recommended that spare contacts be put in place for future use, as incorporating additional contacts as part of the original actuation package incurs comparatively little additional cost.

Employing a properly configured valve automation package, with limit switches delivering valve status or position information to your control system, can yield operational and safety benefits for the life of the unit. Good advice is to consult with a valve automation specialist for effective recommendations on configuring your valve automation accessories to maximize the level of information and control.

Labels:

Arkansas,

Automax,

Flowserve,

Indiana,

Iowa,

Kansas,

limit switch,

Missouri,

Nebraska,

Oklahoma,

Southern Illinois,

valve automation,

Western Kentucky

Safety Relief Valves: The Basics

|

| Safety relief valves by Kunkle |

In generally accepted practices, pressure build-up is relieved by allowing the fluid to flow from an alternate path in the piping system. A safety relief valve is engineered so that it opens at a predetermined pressure setpoint to protect vessel, piping or ancillary equipment equipment from being subjected to pressures that exceed their design limits.

When process pressure is exceeded, a safety relief valve becomes the “weak link”, and the valve opens to divert a portion of the fluid to another path. The diverted liquid, gas or liquid–gas mix is usually routed through a piping system to a process where it is safely contained or burned off via a flaring system. Once the liquid or gas is diverted, the pressure inside the vessel drops below the safety relief valves' re-seating pressure, and the valve closes.

The Data Supplement below presents a wealth of technical information on Kunkle relief valves.

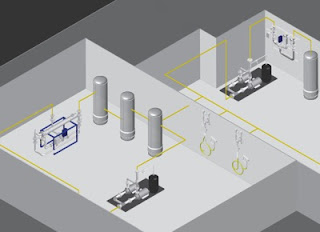

A Modern Industrial Hot Water System Saves Money Through Efficiency and Safety

|

| State-of-the-art hot water heating systems improve efficiency and safety, and increase production and yield. |

By developing a comprehensive strategy that includes state-of-the-art water heaters, water temperature controls, hose stations, variable frequency drive (VFD) pump assemblies and ancillary accessories such as storage tanks, and pressure-reducing valves, processing plants can improve efficiency and safety, and increase production and yield.

Advanced hot water heating systems typically include:

- Steam/water hot water systems with digital control technology and instantaneous heat exchanger design—shell and tube or plate and frame.

- Industrial mixing center with digital control valves, pre-piped as an IMC with requisite installation components for compact design and ease of installation.

- Digital control valves for delivering hot water immediately on demand, and maintained at precision temperatures (+/-1°F, +/-0.5°C).

- VFD pump assemblies application-engineered and configured for your site.

- Hot & cold water hose stations with thermostatic mixing valves that replaces the old, basic Y as the temperature controller.

The brochure below, courtesy of Armstrong International, provides more insight where specific components are used.

Labels:

Arkansas,

Armstrong,

hot water,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Oklahoma,

process heat,

Southern Illinois,

Western Kentucky

Triple Eccentric Disc Valve, Metal Seated, with Flow Balancing Trim

|

| Neles Triple Eccentric Disc Valve, Metal Seated with Flow Balancing Trim |

TRIPLE ECCENTRIC SEATING PRINCIPLE

The disc of the valve is machined to close tolerances to create an elliptical shape similar to an oblique slice taken from a solid metal cone. When the valve is closed, the elliptical disc at the major axis displaces the seat ring out- ward, causing it ring to contact the disc at the minor axis. When the valve is opened, the contact is released and the seat ring returns to its original circular shape.

The S-DISC® control valve unit provides outstanding control performance and excellent long-lasting tightness in the same valve. The very simple and robust construction guarantees long trouble-free operation and maximum reliability.

The S-DISC design consists of a standard NELDISC® triple eccentric disc valve equipped with a flow-balancing trim. The trim has been located on the downstream side of the valve body. The ingenious idea of this design is to transfer fluid forces out of the disc to the body.

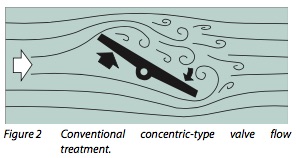

Figures 2 and 3 illustrate the flow treatments with a concentric-type conventional butterfly valve compared to the S-DISC-design. The S-DlSC design offers stable flow control and reduced dynamic torque, noise level and vibrations. The dynamic behavior of the valve is very smooth and stable, which means less load on the shaft bearings, less required torque, smaller actuators and more economical control unit total costs. All of the excellent features of the standard NELDISC are available.

Figures 2 and 3 illustrate the flow treatments with a concentric-type conventional butterfly valve compared to the S-DISC-design. The S-DlSC design offers stable flow control and reduced dynamic torque, noise level and vibrations. The dynamic behavior of the valve is very smooth and stable, which means less load on the shaft bearings, less required torque, smaller actuators and more economical control unit total costs. All of the excellent features of the standard NELDISC are available. The most standard NELDISC can be easily modified to the S-DISC design, just by changing the flange ring.

FEATURES

- Excellent flow and control performance.

- Wide temperature range from -200 ... +600 °C /-330 ... +1110 °F.

- Reduced dynamic torque and noise.

- Mechanical and flow dynamic stability allows higher pressure drop service than a conventional disc.

- ASME 150/PN 20, ASME 300/PN 40 and ASME 600/

- PN 100.

- Sizes DN 80...1500/3"...60"

For more information, visit http://www.meadobrien.com or call (800) 892-2769 for immediate service.

Labels:

Arkansas,

Butterfly valve,

control valve,

Indiana,

Iowa,

Kansas,

Missouri,

Nebraska,

Neles,

Oklahoma,

Southern Illinois,

Western Kentucky

A Magmeter Designed to Withstand the Most Common Failure Modes

|

| Foxboro magnetic flowmeter and transmitter. |

Foxboro magnetic flowmeters, however, solve these industry-wide issues with superior construction, compact design, the widest selection of options, combined with low power consumption.

Foxboro magnetic flow tubes utilize a superior electrode. By using large electrodes, the flowmeter output is less sensitive to the effects of entrained air, and unaffected by higher internal pressures.

Rugged Teflon liners are resistant to chemical attack which makes it possible to use the Foxboro magnetic flowmeter in hard to handle corrosive liquids and slurries.

Finally, Foxboro magnetic flowmeters offer system accuracy of plus or minus 0.25 percent of reading.

Foxboro flow tubes can be paired with there IMT 25 and IMT 96 transmitter for complete compact system that provides unequalled durability measurement accuracy and performance with virtually no maintenance and minimal replacement cost covering the widest choice of industry applications available.

For more information on Foxboro magnetic flowmeters please contact Mead O'Brien at (800) 892-2769 or visit http://www.meadobrien.com.

Subscribe to:

Posts (Atom)