Author: Steve Huffman VP Marketing & Business Development, Mead O'Brien

This article began as a coy reply to Bill Lydon’s interesting “Talk to Me” column (

www.isa.org/intech/201512talk) about Leonardo da Vinci’s accomplishments as an artist applying engineering principles to create engineered works of art. Lydon noted that da Vinci saw science and art as complementary rather than as distinct disciplines. I stated that the word “STEAM,” really STEM + art, was not a new concept. The most recent iteration started sometime within the first decade of the 21st century, gaining traction with the efforts of such influencers as the Rhode Island School of Design beginning in 2010. Lawmakers with whom the Automation Federation met while advocating for our profession on Capitol Hill saw the concept as a way to reach elementary school children who would not otherwise be interested in math, science, and engineering.

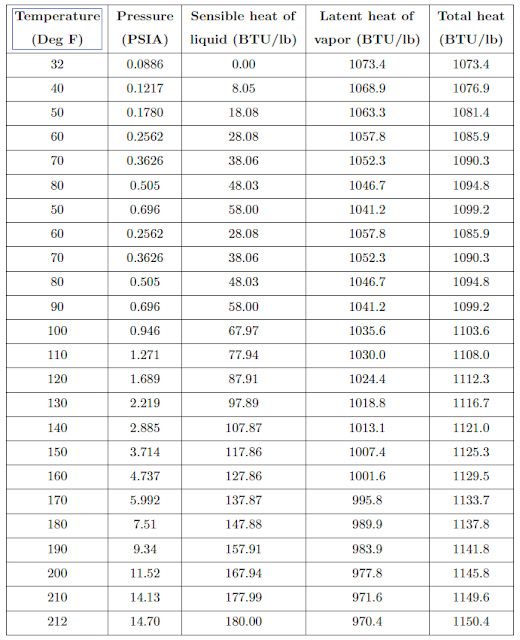

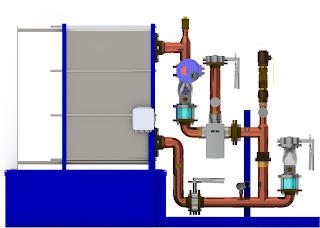

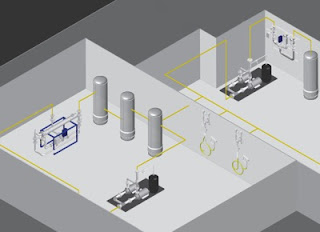

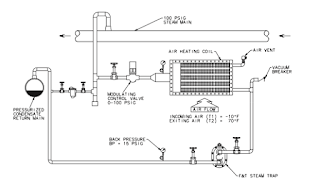

My point was why use the word “steam” and create confusion with the engine of the American industrial revolution—and still the most efficient turbine driver and heat transfer media in prominent use to this day? Ironically, I find a declining knowledge base regarding steam systems used in industry, especially in process control, as the baby boomers are now retiring at very high levels. New practitioners, automation or otherwise, who either work on or are charged with engineering or maintaining these utility systems for process are generally not well prepared from a knowledge or educational perspective. This issue really adds to the negative financial impact that poorly designed or poorly maintained steam systems contribute to product quality, throughput, and energy loss.

For the artistic, it seems someone should have realized that the word, with all its thermodynamic glory, was already taken. So is it right to add “art” to the critical-thinking process of STEM and to the engineering curriculum to add another dimension to the student’s education? A number of artists and engineers disagree, but mainly because they only view their “discipline” as a tool that makes the other “discipline” superior. In short, it does go both ways, and purists on both sides probably resent that art and engineering go together. Because we come from the engineering side of the fence, I feel that art probably does broaden the horizons of engineers, but bringing art into engineering certainly does nothing to diminish art in and of itself. As art teaches us, there are many ways to comprehend the same thing.

In my own experience with the brewing industry in St. Louis over the past 40 years, the process mix includes engineering, science, and the application of the art of brewing, which goes back to the ancient Greeks. Modern brewing evolved over the past 150 years with people from those disciplines working together, some even using the “glue” of automation to turn their processes into highly automated, high production, and sophisticated dynamos with dozens of new products released yearly, all of them starting with four basic ingredients.

I project that art in STEM (STEM+A if I were chief acronym maker) is absolutely necessary for automation professionals to better appreciate process and better visualize what the future holds. It is also essential for thinking more abstractly, and in homage to the next big thing, developing a critical eye to analyze, put to practical use, and translate from “production-speak” to meaningful “management-speak” the massive amount of data coming our way with the Industrial Internet of Things revolution of which we are on the cusp. Dealing with disruptive technologies in process and factory automation will require digital skills far in excess of what we can even see on the horizon today. It seems that steam may be creating some buzz, but in the future the real kinetic energy will be created by digital engineers.